CLOSED DIE FORGING

As a professional supplier starting from 2002, we have quite good forging manufacturers which have ISO9001:2000, TS16949 certificate and can make most types of forging for automotive, oil, Chemical, Valve, Medical, Metallurgical, Mine etc.

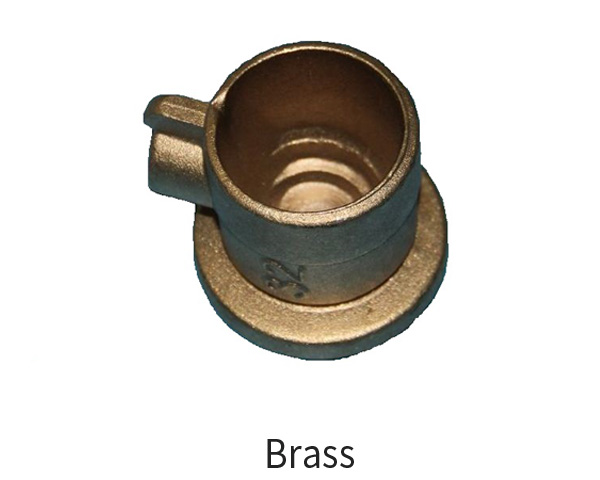

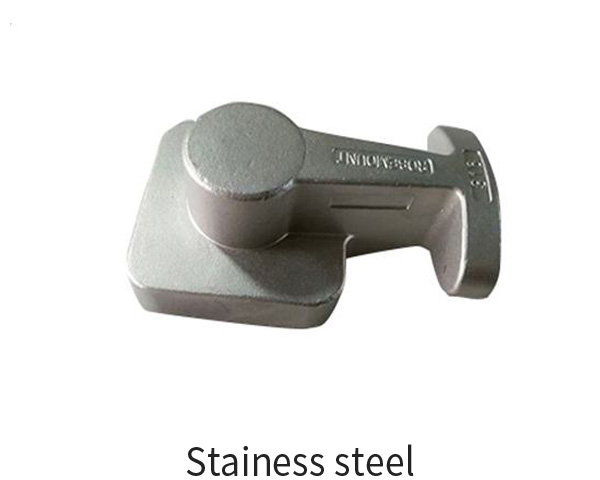

Forging material can be Carbon steel, Low alloy steel, stainless steel, Aluminum, copper etc. And all materials will be confirmed to standard: SAE, ASTM, DIN, BS, JIS, and ISO etc

●Die-closed forging: Carbon steel, Low alloy steel, Stainless steel, Aluminum, Aluminum, copper etc.

Forging weight: 0.011lb~110lbs (0.005kg~50kgs)

●Ring-rolled forging:

√Aluminum: material 1xxx, 2xxx, 3xxx, 5xxx, 6xxx,7xxx etc with Heat treat,

Ring size: OD: 8”- 32”, Thickness: 0.6 -4”, Length: 0.4”- 24”

√Carbon steel and low alloy steel: all type, 0.011lb~110lbs (0.005kg~500kgs)

√Stainless steel: 304, 316 etc, 0.011lb~110lbs (0.005kg~500kgs)

●Open die forging: Carbon steel, alloy steel, Stainless steel, Aluminum

Forging weight: 0.011lb~110lbs (0.005kg~500kgs)

We can work on a “turn-key“part, or provide you raw forging or rough machined forging. And we can take “Total Product Responsibility” by including machining; heat treating (including Carbonizing, etc.), coating, anodizing, polishing (including electrolytic polishing) and plating.

Forging has better mechanical than casting. If your part is well for forging, forging is the first option. If you cannot decide, we shall provide you our suggestions for your decision to use casting and forging. We shall carefully scrutinize your part design and your requirements and also discuss with suitable manufacture to give you a confirmation so that you are confident with your parts ideally suited to your needs before proceeding.

What we need is a print or a sample; you can get our free valuations for your parts.