H&E is committed to providing the highest quality products and materials to its customer. To achieve this goal, H&E has built a system of dimension inspection and quality control based on ISO9001 as part of the H&E Quality Procedures. For dimension inspection, We usually complete the following:

● Random dimensional inspection is performed on all as-cast part.

● 100% inspection to threads

● 100% inspection for machined features of part to verify compliance with our customers’ requirements. Copies of these reports can be provided upon request.

For common gauge o f English/American standard system, we usually use gauge made from USA. or use the same gauge as customers' use.

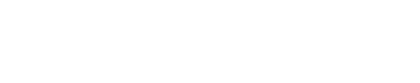

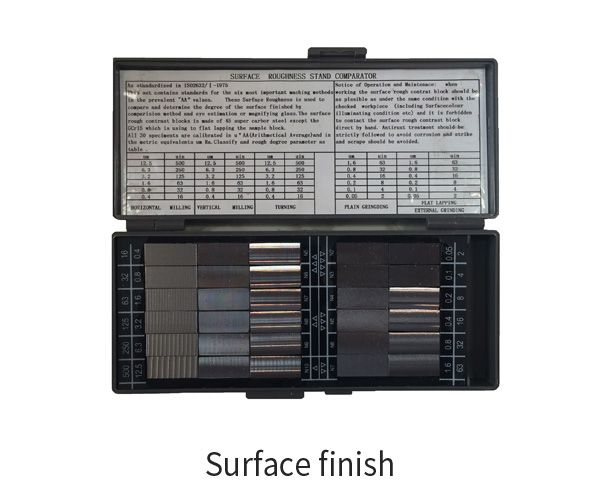

Special inspection gauge will be designed by H&E's engineer and made by professional tooling suppliers or provided by customers.

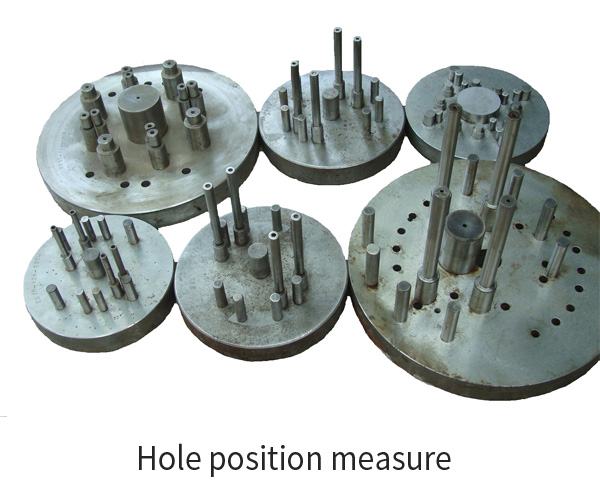

Our responsibility is to provide our customers' qualified parts. We use the simplest and most steady inspection tooling/method to ensure all features to print. Inspection tooling will be calibrated every two years. For some tooling being used frequently, will calibrate periodically.

Any parts , if its dimension is out of size---oversized or below-size will be picked out.

● Random dimensional inspection is performed on all as-cast part.

● 100% inspection to threads

● 100% inspection for machined features of part to verify compliance with our customers’ requirements. Copies of these reports can be provided upon request.

For common gauge o f English/American standard system, we usually use gauge made from USA. or use the same gauge as customers' use.

Special inspection gauge will be designed by H&E's engineer and made by professional tooling suppliers or provided by customers.

Our responsibility is to provide our customers' qualified parts. We use the simplest and most steady inspection tooling/method to ensure all features to print. Inspection tooling will be calibrated every two years. For some tooling being used frequently, will calibrate periodically.

Any parts , if its dimension is out of size---oversized or below-size will be picked out.