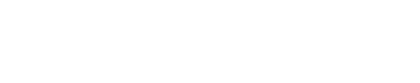

DESIGN ASSISTANCE

Hits:3114

From your concept to actual part, H&E can provide full set of services!

H&E's staff specializes in a suite of CAD and CAM software. We can help carry your ideas from start to completion, developing and optimizing your 3D models for FDM & SLA 3D printing, rapid prototyping, and CNC machining and secondary process like: heat treating (including Carbonizing, etc.), coating, polishing (including electrolytic polishing) and plating

This allows us to move from the more traditional methods of pattern making to a three-dimensional computer generated model. By simulating the functionality of your model in our CAD/CAM Software, we discover solutions that increase your productivity. This allows us to utilize CNC machining to increase dimensional accuracy. We can also utilize customer supplied solid models to save time and reduce costs.

We also using SOLIDWORKS to offer fully integrated plastic, cast part and mould design to allow for design validation: draft, thickness and undercuts can all be monitored to check for suitable geometry for tooling/pattern.

We help our clients in converting their conceptual ideas to standard and precise 3D manufacturing drawings and actual part production.

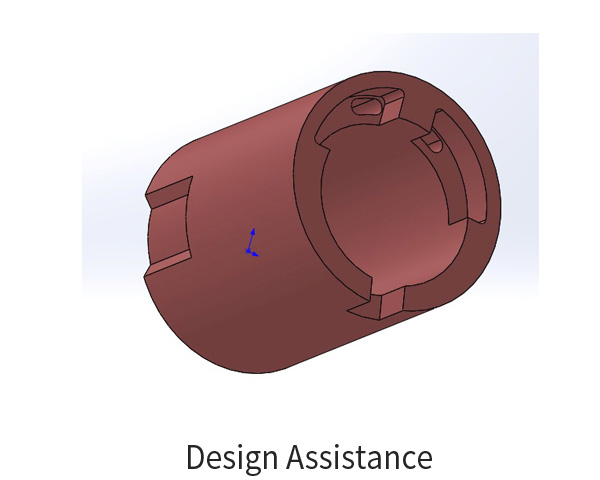

From concept design to actual production, One STOP at H&E

H&E's staff specializes in a suite of CAD and CAM software. We can help carry your ideas from start to completion, developing and optimizing your 3D models for FDM & SLA 3D printing, rapid prototyping, and CNC machining and secondary process like: heat treating (including Carbonizing, etc.), coating, polishing (including electrolytic polishing) and plating

This allows us to move from the more traditional methods of pattern making to a three-dimensional computer generated model. By simulating the functionality of your model in our CAD/CAM Software, we discover solutions that increase your productivity. This allows us to utilize CNC machining to increase dimensional accuracy. We can also utilize customer supplied solid models to save time and reduce costs.

We also using SOLIDWORKS to offer fully integrated plastic, cast part and mould design to allow for design validation: draft, thickness and undercuts can all be monitored to check for suitable geometry for tooling/pattern.

We help our clients in converting their conceptual ideas to standard and precise 3D manufacturing drawings and actual part production.

From concept design to actual production, One STOP at H&E